Technology advances make 3D digital tank analysis effortless.

Ever since the origins of tank storage, there has been a need to understand tank capacity and integrity. It’s not hard to imagine Jack Daniels and master distiller Nathan Green holding frequent discussions in 1864 about the volume and potential leakage of their kegs. Today, more than 150 years later, the same concerns that kept Nathan and Jack awake at night still keep those responsible for tank maintenance sleepless.

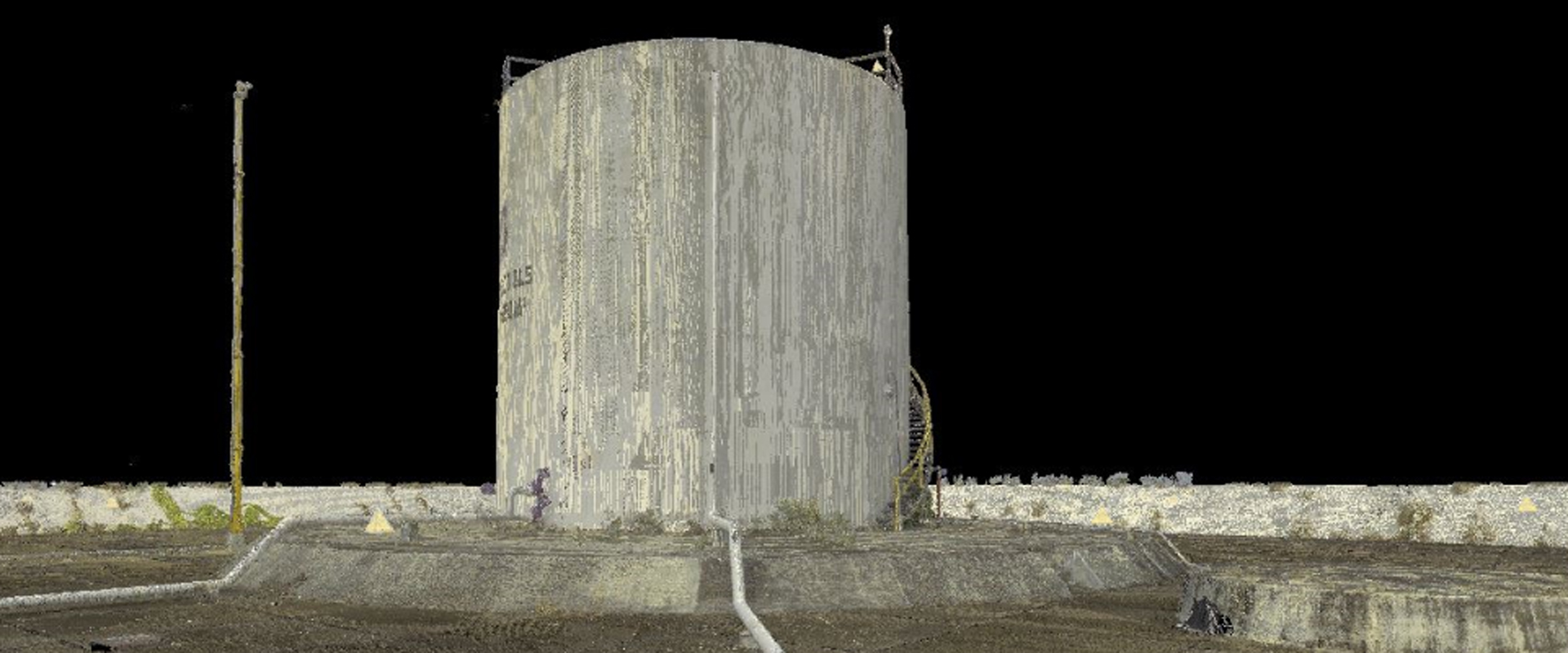

Fortunately, the methods used to analyze tank volume and integrity have advanced significantly. With 3D laser scanning, a non-contact and nondestructive method of digitally capturing physical objects in 3D using a beam of light, or laser, millions of measurement points can be captured on the tank’s surface. These combined points are known as a point cloud—a clear and precise digital record of the tank that can be used for analysis and maintenance.

Read the article in the Spring Edition 2019 of Tank News International.