...they’re used to handling time-sensitive requests, but this was the tightest deadline the firm had ever encountered.

As the Greenway Pollution Control Plant’s dewatering facility neared the end of its life, Geordie Gauld, division manager of wastewater treatment operations for the City of London in Ontario, Canada, faced a seemingly impossible predicament. The city planned to repurpose the existing dewatering building into an advanced technical research facility for testing new wastewater technologies.

Company

R.V. Anderson Associates Limited (RVA)

J-Tech Laser Scan

Location

London

Ontario, Canada

To help accomplish this project, the Federal Economic Development Agency for Southern Ontario had offered a grant of about $4.4 million. To qualify for the funds, however, London had to complete construction of the research facility by March 2014. Timing was tight because it was already April 2011, and the City could not start repurposing the facility until they built a new dewatering plant. To do so, they needed to install three centrifuges, as well as sludge feed and polymer feed pumps. To complicate matters, the proposed building for the new centrifuges and pumps was the home of an abandoned incinerator that was built in the 1960s and contaminated with asbestos and a congested maze of pipes. Before contractors could start any renovations, they needed to demolish the incinerator. Also, the finished design had to fit within the existing structures, leaving no room for error. Existing as-built records of this facility were inadequate for the design team’s needs, and the planned demolition made it impossible for them to visit the site when they needed to begin the project.

When Gauld presented the problem to several engineering companies, it’s not surprising that most of them told him that design would have to wait until after the demolition. Waiting was the easiest answer; however, it would delay the project by at least six months and put federal grant dollars at stake.

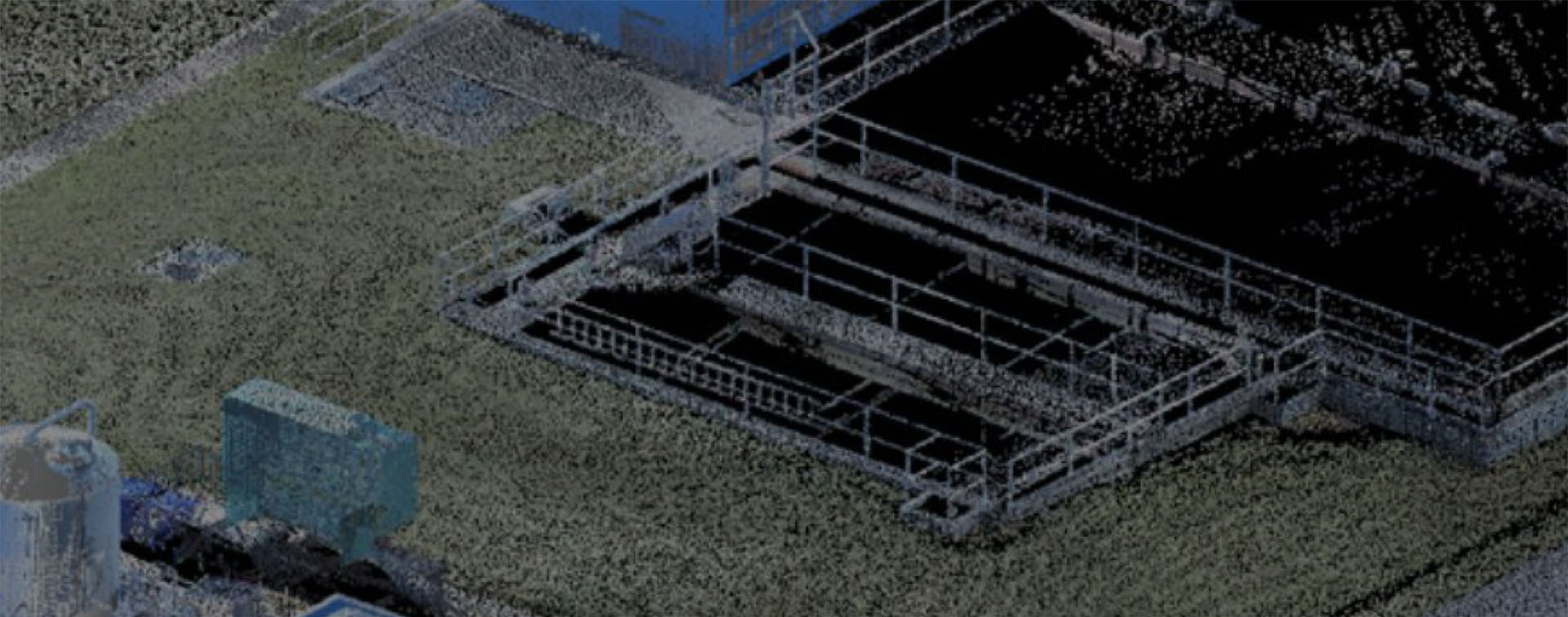

The ability to “as-built” the existing structure prior to the incinerator demolition enabled designers to complete the new facility design virtually.

Breaking Out of the Box with Laser Scanning Technology

With this streamlined process, it took the crew only five days to capture twenty-eight scans and document five building levels.

Luckily, David Evans, associate director and regional manager of R.V. Anderson Associates Limited (RVA), a professional engineering firm, broke away from conventional thinking and conceived an innovative approach to the project. He and his team make it a priority to stay abreast of new technologies, and had attended a demonstration by J-Tech Laser Scan in 2010. The company, located in Ontario, was an early adopter of 3D laser scanning technology and is a premier Leica Geosystems High Definition Survey (HDS) service provider. At this event, they learned how surveyors can use a laser scanner to sweep a laser beam over a site, capturing detailed three-dimensional data on existing structures. The result is a point cloud which includes millions of data points in three dimensions, representing the scanned area. This information enables designers to visit a plant virtually, and design from the controlled conditions and comfort of their offices. If the RVA designers could “as-built” the building prior to demolition day, they would be able to complete the design virtually, averting delays and enabling the City to meet the schedule for the federal grant.

So, RVA enlisted the help of J-Tech Laser Scan to survey existing process equipment, piping, valves, pumps and more. Jonathan Paterson, project manager, estimator and mechanical engineering technologist, chose to use the Leica ScanStation C10 to gather the data. Given the critical timeline for the project, he felt it made sense to choose a scanner with survey grade accuracy that can capture data fast, at up to 50,000 points a second (the standard for plant applications at that time). Also, logistics were easier because the scanner allowed J-Tech’s technician to move around freely—it had an untethered battery and Wi-Fi remote control.

Fieldwork went smoothly, not only because of the advanced, easy-to-use technology but also J-Tech’s rigorous upfront planning and detailed scope of work. Paterson worked with Greenway’s leaders to coordinate J-Tech’s work schedule around the organization’s activities. Also, prior to scanning, J-Tech’s crew did reconnaissance to set up discrete controls and witness marks which would help ensure an accurate, efficient scanning process. They also determined the scanning progression, including how they would move around physical objects and the necessary intervals between stations. A solid plan was essential to make sure they scanned features of interest from all necessary angles since a laser scanner can only capture what is within its line- of-sight. Once J-Tech had structured the operation, their two-man crew, a foreman and a manager of quality assurance and safety, instituted an efficient, safe scanning process. At each station, the crew set up the laser scanner and acquired discrete control targets. Then, they performed a 360-degree general scan at the specified resolution and focused on critical features at higher resolution. After they had taken photographs, they dismantled the equipment and moved to occupy the next station. With this streamlined process, it took the crew only five days to capture twenty-eight scans and document five building levels.

Using a Leica ScanStation enabled the J-Tech crew to rapidly capture accurate, comprehensive data on the dewatering facility.

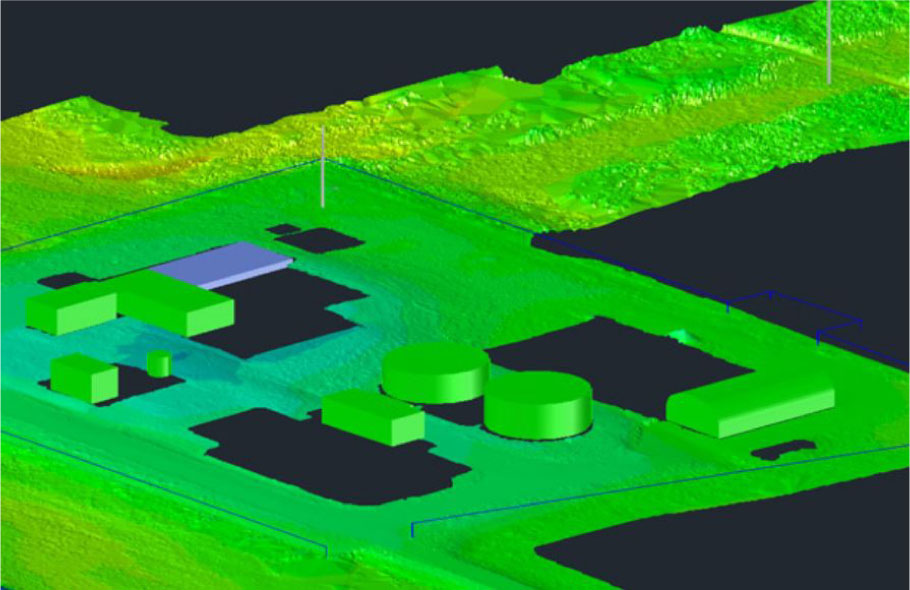

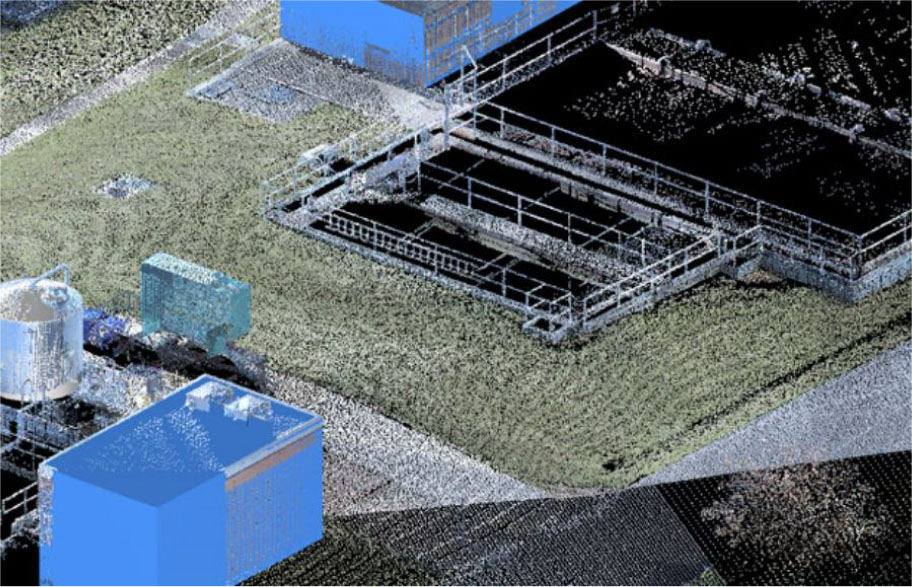

Back in the office, J-Tech’s mechanical designer spent five days processing the data using AutoCAD and Leica Cyclone 3D point cloud software. Paterson says they use Leica Cyclone software “because of its highly sophisticated analytical and optimization algorithms and easy workflows.” They provided RVA with point clouds, TruViews, dimensional photographs that designers can superimpose on the point clouds, and a CAD model of the primary steel structures. When viewed in Leica Geosystems’ free TruView panoramic viewer, TruViews provide a photo-realistic depiction of the site. R.V. Anderson’s designers were able to examine the TruViews from all angles to gain an understanding of how the plant elements fit together and determine where they could connect the new components. Also, when they had questions about specific pipes or valves, they could zoom in on them to gain answers immediately. Finally, using Cyclone Publisher, RVA was able to show their clients a rich visual representation of how the new equipment fit in the existing structure, making it easier for them to visualize and approve the layout.

Six-Digit Savings and Better Results

Over the course of the project, the virtual design saved four weeks in man hours that would have been required for travel and plant visits.

With the aid of these cutting-edge tools, the design team was able to complete the structural, mechanical and electrical design in their Toronto office, two hours away from the wastewater plant. Over the course of the project, the virtual design saved four weeks in man hours that would have been required for travel and plant visits. The travel cost savings alone approximated $20,000. Also, R.V. Anderson’s return trips would have been particularly costly due to the need for asbestos abatement. Had the crew needed to return, they would have required specialized training, and would not have been able to do dimensional field checks via traditional means. Finally, Evans points out that when it’s necessary to take a trip to gather new data, projects are often on hold until designers can complete the data acquisition. Thus, the virtual visits sped up project turnaround time. Also, because visualization was so easy, the team checked details they might have had to pass over if they were using traditional design techniques.

Evans believes the more comprehensive and accurate data, combined with an increased focus on the fine points, led to improvements in the design quality, enabling RVA to complete a design that had no major clashes. Given the size and complexity of the retrofit project and industry averages for rework, which range from 10-20%, Evans estimates that their high-tech process saved $100,000. Paterson agrees and adds, “Construction costs increase about ten-fold at every phase of the manufacturing process when errors occur and are not detected and corrected. The value of accurate data upfront is tremendous.”

R.V. Anderson’s designers were able to examine the TruViews from all angles to gain an understanding of how the plant elements fit together and determine where they could connect the new components.

No Turning Back

The designers complain bitterly if we have not got the TruView data for them to work with,’ Evans explains. “They now feel blind when looking at ‘old fashioned’ drawings and trying to visualize a space.

Gauld was thrilled that the project was delivered on time, allowing the federally funded technical research facility construction to begin as scheduled. London’s representatives were so impressed with laser scanning capabilities that they now prefer it on all projects. They are even considering using it to capture as-builts for older facilities where documentation is out of date. As for R.V. Anderson, they now use laser scanning for all plant projects. “The designers complain bitterly if we have not got the TruView data for them to work with,” Evans explains. “They now feel blind when looking at ‘old fashioned’ drawings and trying to visualize a space. They don’t want to find out at the 11th hour that we have placed a piece of equipment in an area that is too small. That kind of error severely disrupts our design schedules and negatively impacts budgets.”

The Greenway Pollution Control Plant dewatering upgrades project won the 2014 Technical Innovation Award from the Ontario Public Works Association in large part due to R.V. Anderson’s ability to employ laser scanning to overcome the project’s challenges. In addition, RVA was given credit for providing a sustainable solution, and re-purposing a building on a tight site, and reducing capital costs and operational complexity.

Having access to accurate point clouds enabled designers to easily find answers to questions about specific pipes or valves without the need for additional site visits.

HIGH-VALUE DELIVERABLES

- High resolution registered point clouds

- Leica TruViews

- Dimensional photographs

- 3D models

BENEFITS

Increased Safety

All data captured from ground level

Fast Data Collection

All data captured in five days; saved four weeks of man hours and approximately $20,000 in travel costs compared to conventional processes

Comprehensive Data Capture

Complete and accurate as-is dataset can be reused for future projects; accurate, comprehensive data enabled virtual interference checks and saved an estimated $100,000 in typical industry rework costs

Better Project Visualization

3D models enable stakeholders to make better decisions