The best approach – and really the only approach for complex situations like tall underground storage tanks – is to rely on experts skilled at using 3D laser scanning.

Deep within the rock of a volcanic mountain ridge, 20 steel-lined upright cylindrical tanks stand encased in concrete. Each tank measures 100 feet in diameter and 250 feet tall and can store 12.5 million gallons of fuel. Careful inspection and maintenance of the tanks is crucial to protect the region’s drinking water supply and maintain the storage facility as a strategic resource. But how can comprehensive measurement data be safely obtained on such tall tanks below ground?

Location

Crockett, Calif.

“The conventional approach for any kind of tank calibration or survey is to use a linear measurement method, such as total stations or tape measures,” says D’Arcy Trask, high-definition survey specialist and owner of Gauge Point Calibration Inc., based in Crockett, Calif. “But that really limits the amount of information you can capture on a tank; you might only be able to get about 250 points of measurement with those methods, and you’re working at elevation with tie-off and fall protection, trying to get the data you need. It’s hazardous, time consuming and prone to error. The best approach – and really the only approach for complex situations like tall underground storage tanks – is to rely on experts skilled at using 3D laser scanning.”

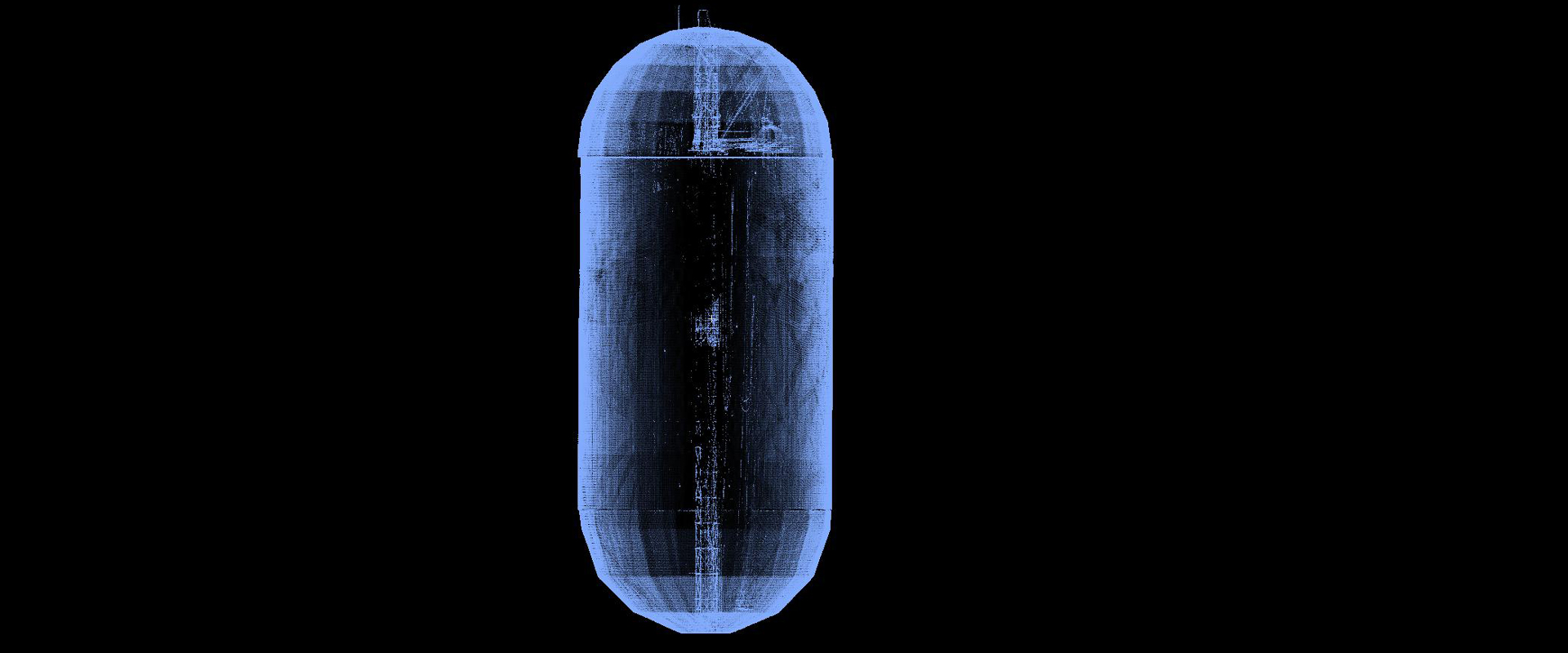

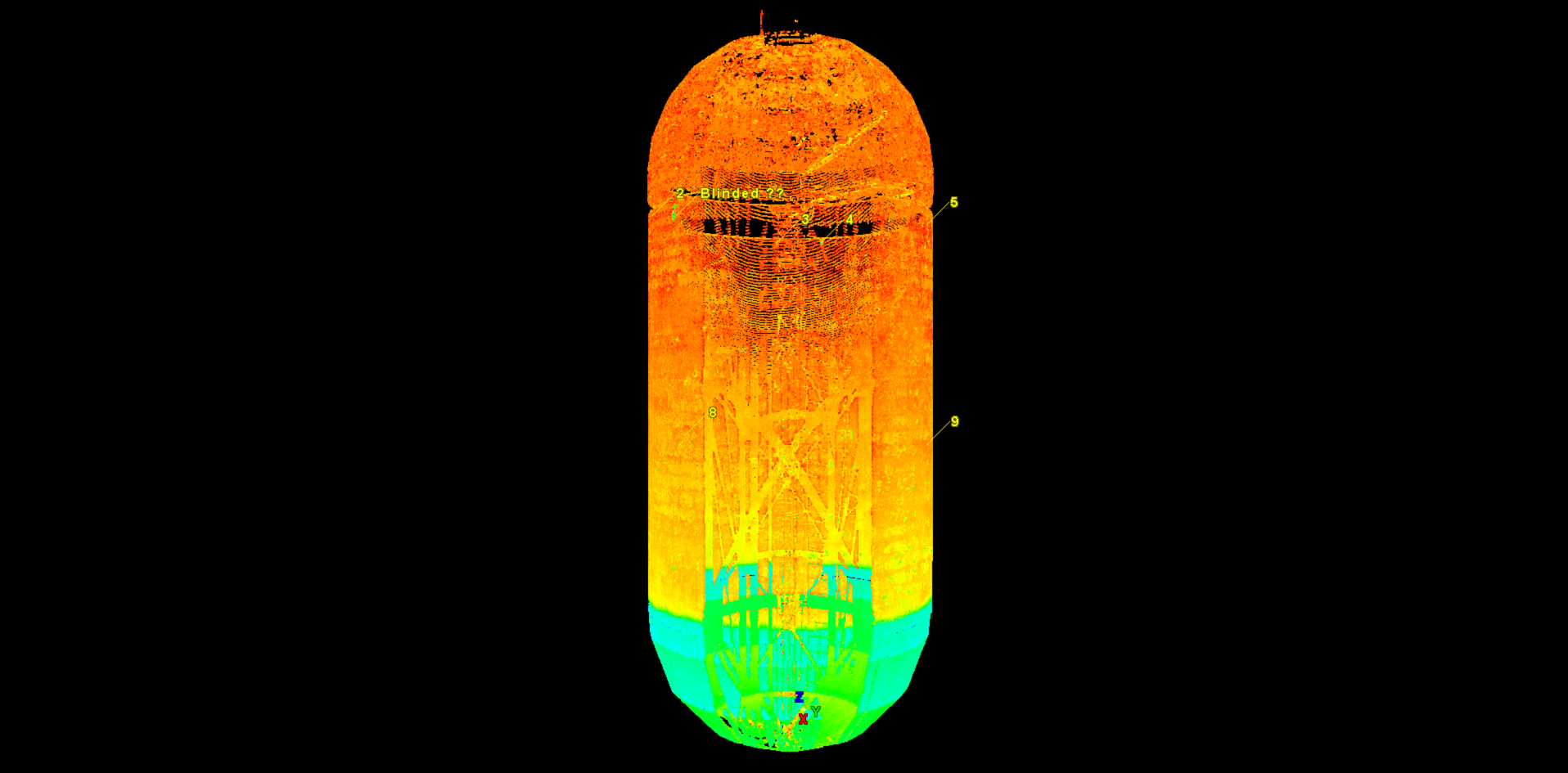

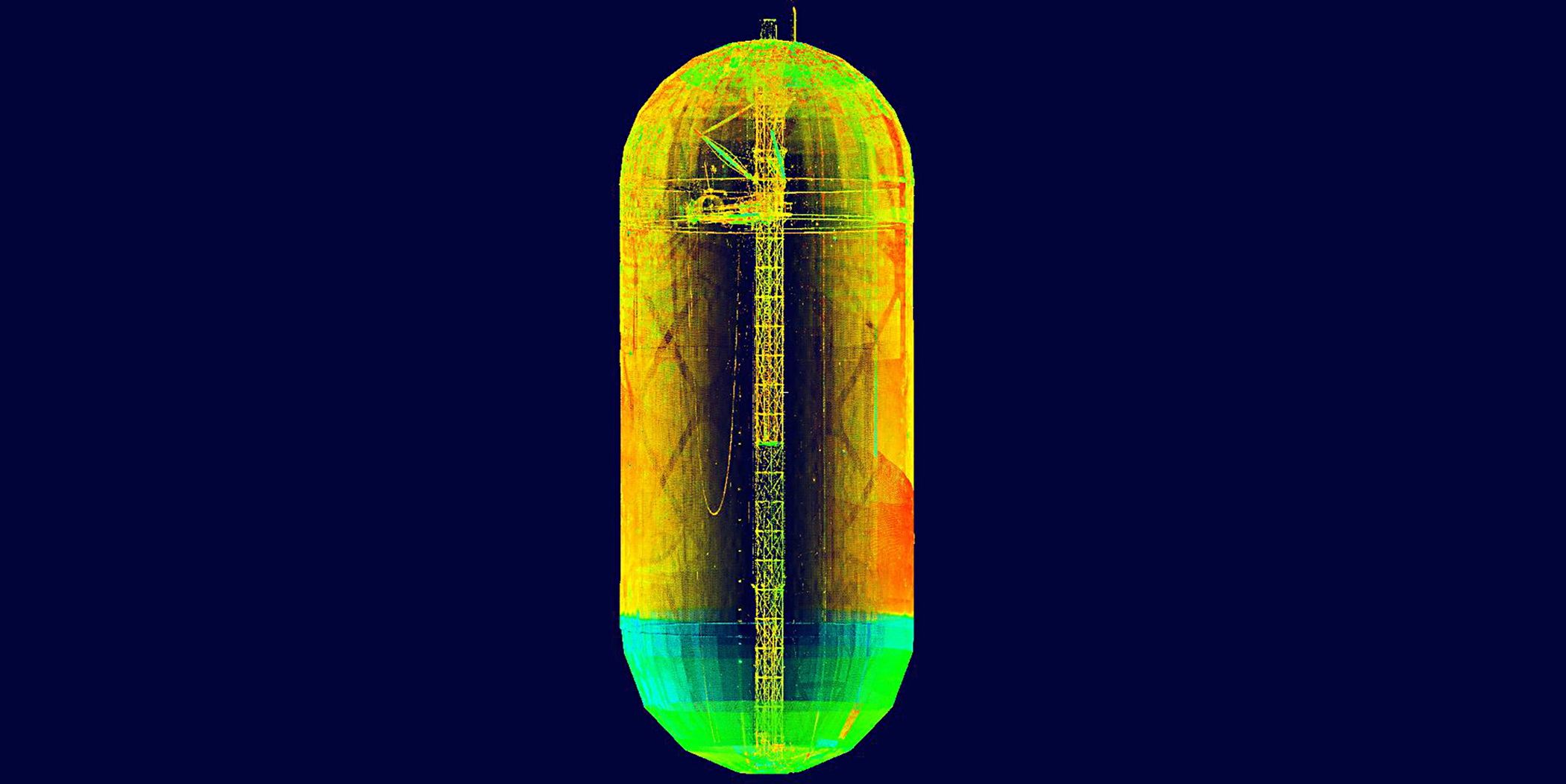

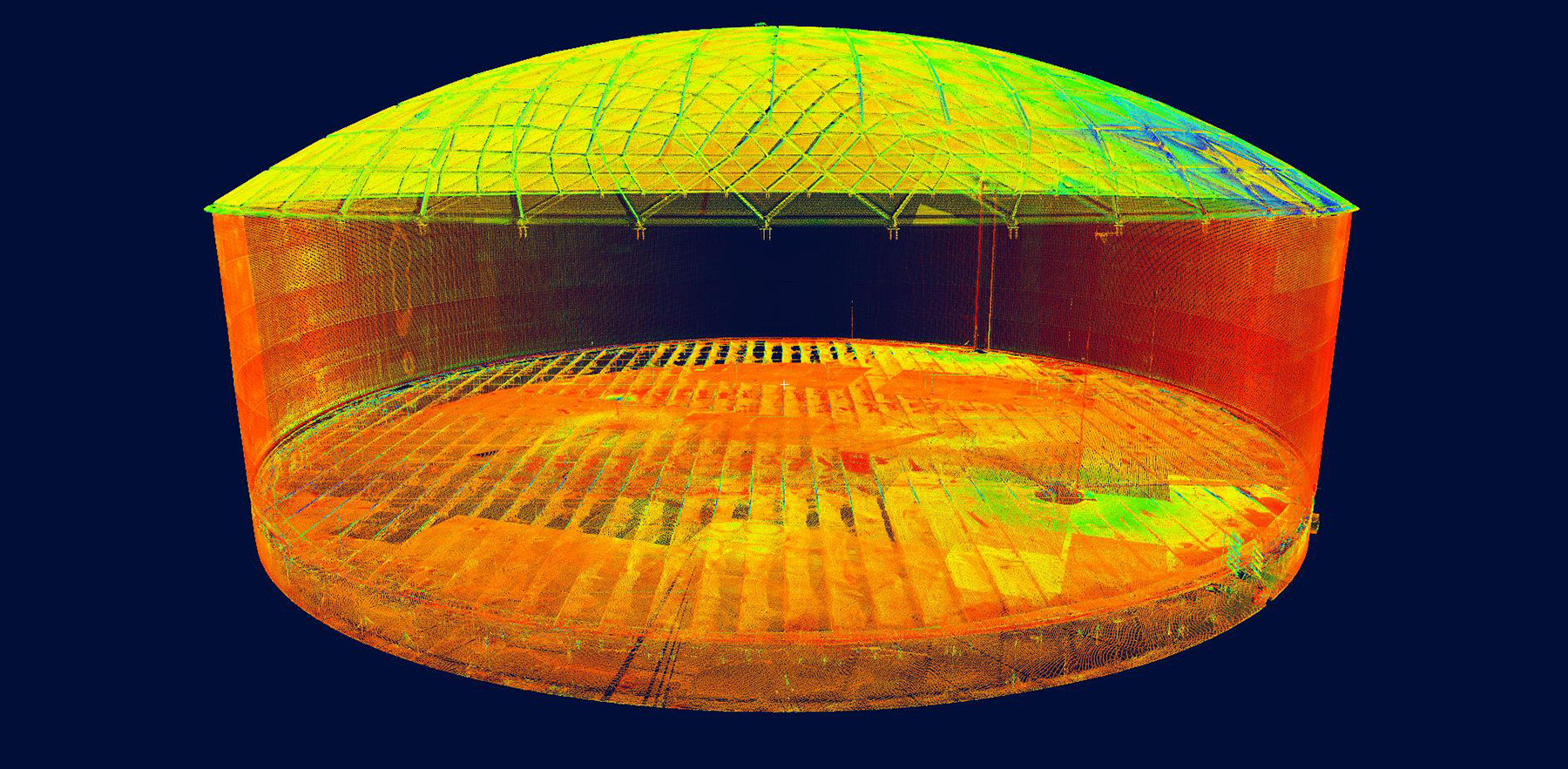

Laser scanning captured comprehensive measurement data on these 250-foot-tall underground tanks. The tanks were scanned from the inside and outside to create the registered models shown here.

3D Laser Scanning Provides Comprehensive Tank Intelligence

A picture is worth a thousand words, so as soon as our clients see the point clouds and 3D models, they immediately understand the value.

Gauge Point Calibration has been calibrating storage tanks for 27 years and has done work for every major oil company in the United States as well as the U.S. Navy on both underground and above ground facilities. Thirteen years ago, the company began using high definition 3D laser scanners from Leica Geosystems to capture tank data. It was a turning point for the firm.

“Instead of capturing a couple hundred measurement points on a tank, we were able to safely capture millions or billions of highly accurate points from the ground, which provided much more clarity on the tank’s condition and status,” Trask says. “We were able to bring that tank back into the office in a 3D environment and obtain measurements we couldn’t have gathered before due to the risk of inaccuracies or incomplete data.”

The company invested in more Leica Geosystems laser scanners and software and soon mastered the technique of providing high-definition laser facility and tank surveys. “Leica Geosystems laser scanners are the standard in the industry and are known for their uncompromising accuracy and seamless workflows,” Trask says. “Adding this capability to our expertise in tank calibration and surveying enabled us to provide a whole new level of service to our clients.”

With 3D laser scanning, Gauge Point Calibration’s deliverables became much more comprehensive. In addition to providing basic calibration reports to the API MPMS 2.2D standard, the company was able to help clients manage operational risk and monitor for damage, overfill and environmental levels to meet the API 2350 standards. It was able to perform conceptual design and interference checks and help clients conform to API standards 650 and 653 for maintenance and inspection.

Gauge Point was also able to provide information in an easily accessible, highly visual format. “A picture is worth a thousand words, so as soon as our clients see the point clouds and 3D models, they immediately understand the value,” says John Barrella, Gulf Coast regional manager. “Our approach is basically that ‘we bring the tank to you.’ 3D laser scanning is a powerful tool.”

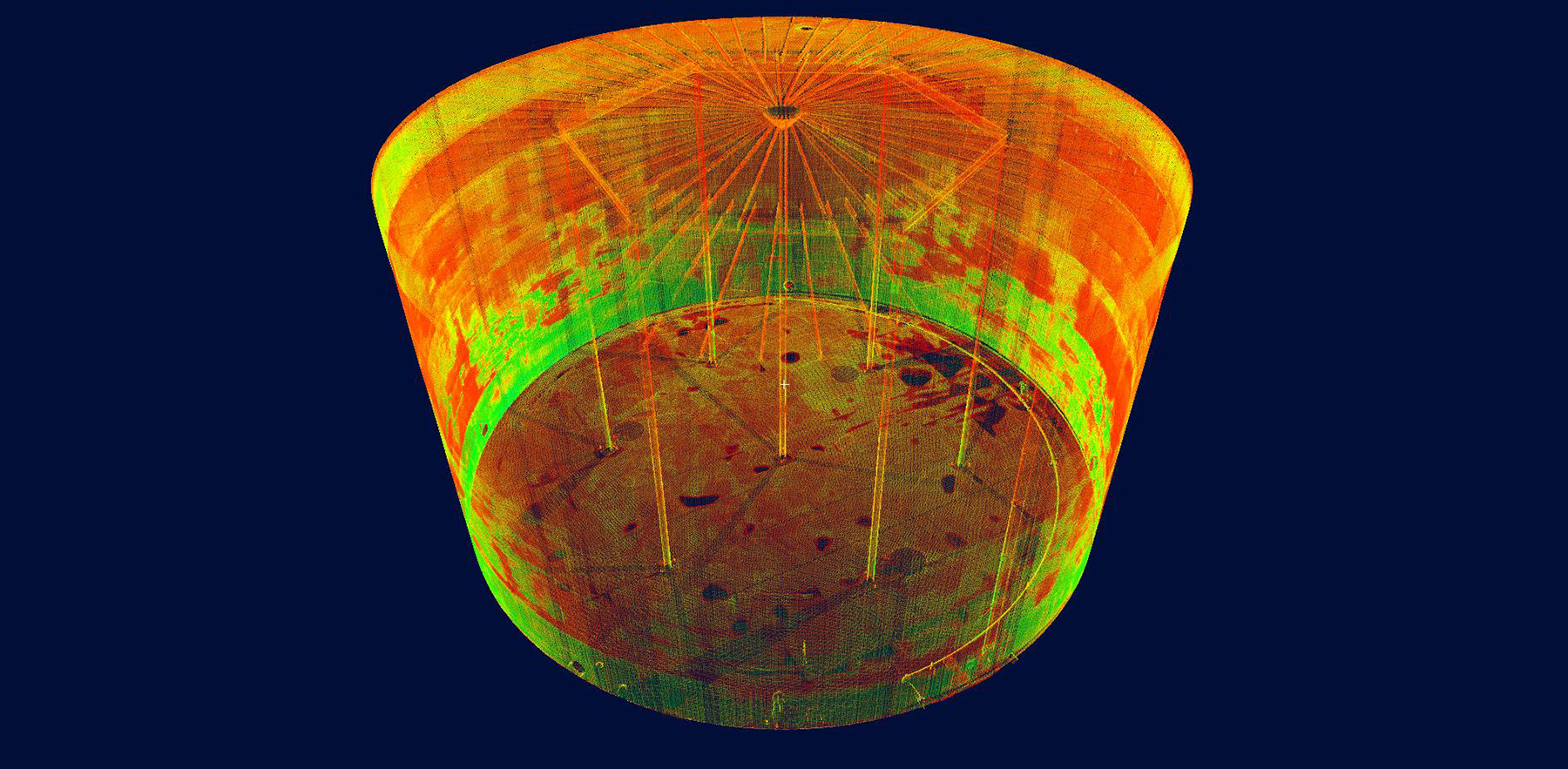

3D laser scanning can be used to create calibration reports; manage operational risk; monitor for damage, overfill and environmental levels; and create maintenance and inspection reports. Pictured here is a registered model of the interior of a floating roof tank.

3D Laser Scanning Provides Long-Term Value

A basic calibration chart really isn’t good enough anymore. With the transition to digitalization, organizations want to ... pull up a 3D model of their tanks and analyze comprehensive data to identify problems and overcome challenges.

While the immediate benefits of having accurate, easily accessible and visual tank data are widely recognized, there is another advantage that tank owners don’t often consider: the ability to return to the dataset to mine additional information in the future. “When you work with a reputable service provider, they can help you maximize the return on your initial laser scanning investment, which can save you time and money later on,” explains Barrella.

For example, comprehensive point cloud data captured for a tank calibration can become the foundation for design and engineering drawings if future facility modifications are needed, minimizing or even eliminating the need for additional surveys. Point clouds can also be compared to original as-builts or older scans to identify areas of deformation or corrosion before they cause problems, reducing risk and saving repair costs.

“A basic calibration chart really isn’t good enough anymore,” says Trask. “With the transition to digitalization, organizations want to work with a trusted business partner that can pull up a 3D model of their tanks and analyze comprehensive data to identify problems and overcome challenges. They want to rely on experts who can help them manage their tank integrity programs by providing exceptional data in a visual, digital format. High definition surveying with 3D laser scanning is an enabling technology that delivers tremendous value.”

Laser scanning data is available in an easily accessible, highly visual format. Shown here is a registered model of an internal floating roof tank with a geodesic dome.

Learn more about Gauge Point Calibration or Leica Geosystems 3D Laser Scanning solutions, or contact us for a consultation on your project needs.

HIGH-VALUE DELIVERABLES

- Calibration reports to the API MPMS 2.2D standard

- Reports for operational risk as well as damage, overfill and environmental levels to meet the API 2350 standards

- Conceptual design and interference checks to ensure conformance to API standards 650 and 653

- All data in an easily accessible, highly visual format

BENEFITS

Increased Safety

All data captured from ground level

Comprehensive Data Capture

Accurate, comprehensive measurements that couldn’t be gathered through any other means due to the risk of inaccuracies or incomplete data

Better Visualization

TruViews and 3D models enable stakeholders to make better decisions