Using reality capture, our team has the ability to be in and out of a job site in a fraction of the time it would take a traditional survey crew, inspecting hard-to-reach places safely and easily to take risk out of the equation.

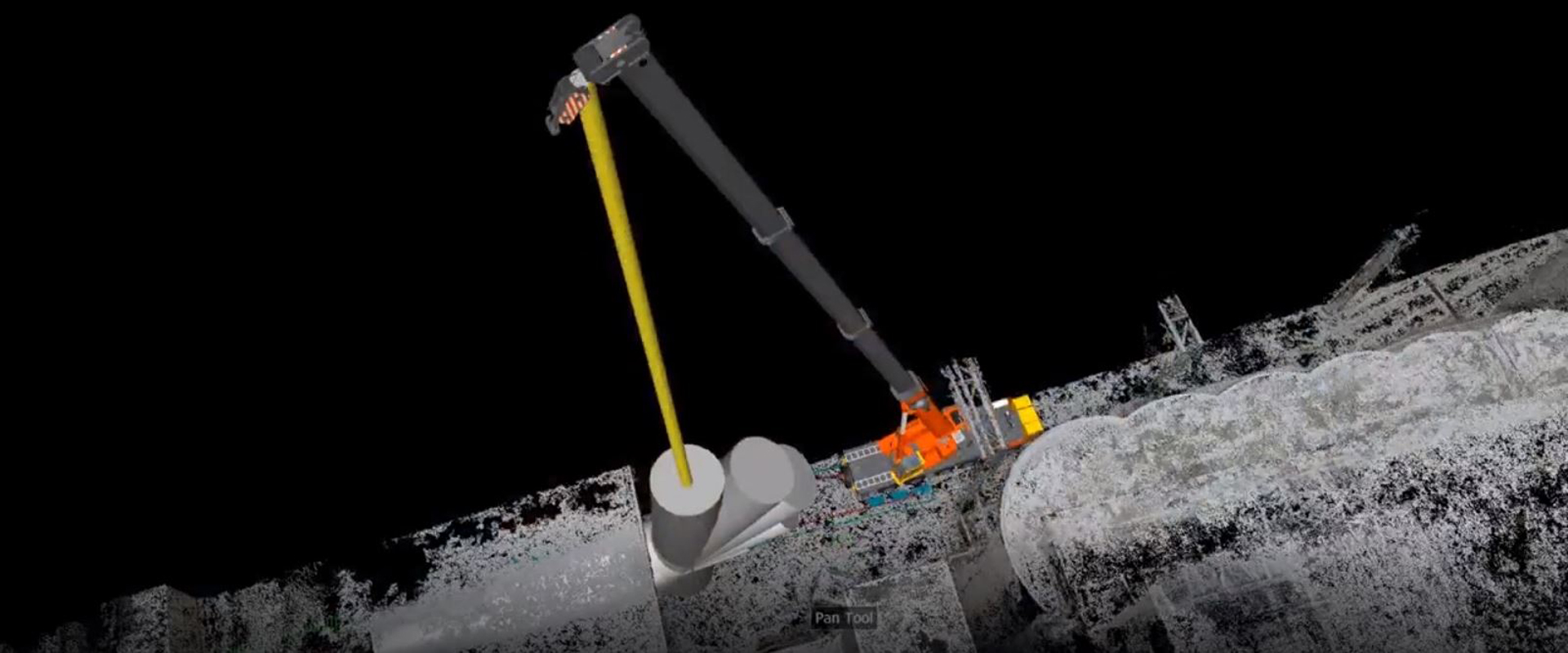

Replacing food storage silos should be an easy task. But when new silos need to be installed in a confined space through a meticulous rigging and installation process, there’s only one way to avoid shutdowns and schedule delays.

In an engaging interactive case study, global project delivery firm SSOE details how using a combination of drone/UAV technology and high-definition terrestrial laser scanning technology enables accurate data capture of the existing site conditions and a full understanding of the installation area. This approach simplifies surveys, inspections, and logistics; improves safety; and saves time by enabling models to be created with minimal action from end users. “Using reality capture, our team has the ability to be in and out of a job site in a fraction of the time it would take a traditional survey crew, inspecting hard-to-reach places safely and easily to take risk out of the equation,” SSOE says. (Related: Read how laser scanning an existing food processing facility can help with buildout of a new or customized operation.)