Personnel safety and inventory accuracy are paramount in tank analysis and maintenance, regardless of the material being stored. Joel Hurt, Jr., vice president of industrial plant solutions for Leica Geosystems, part of Hexagon, explains further.

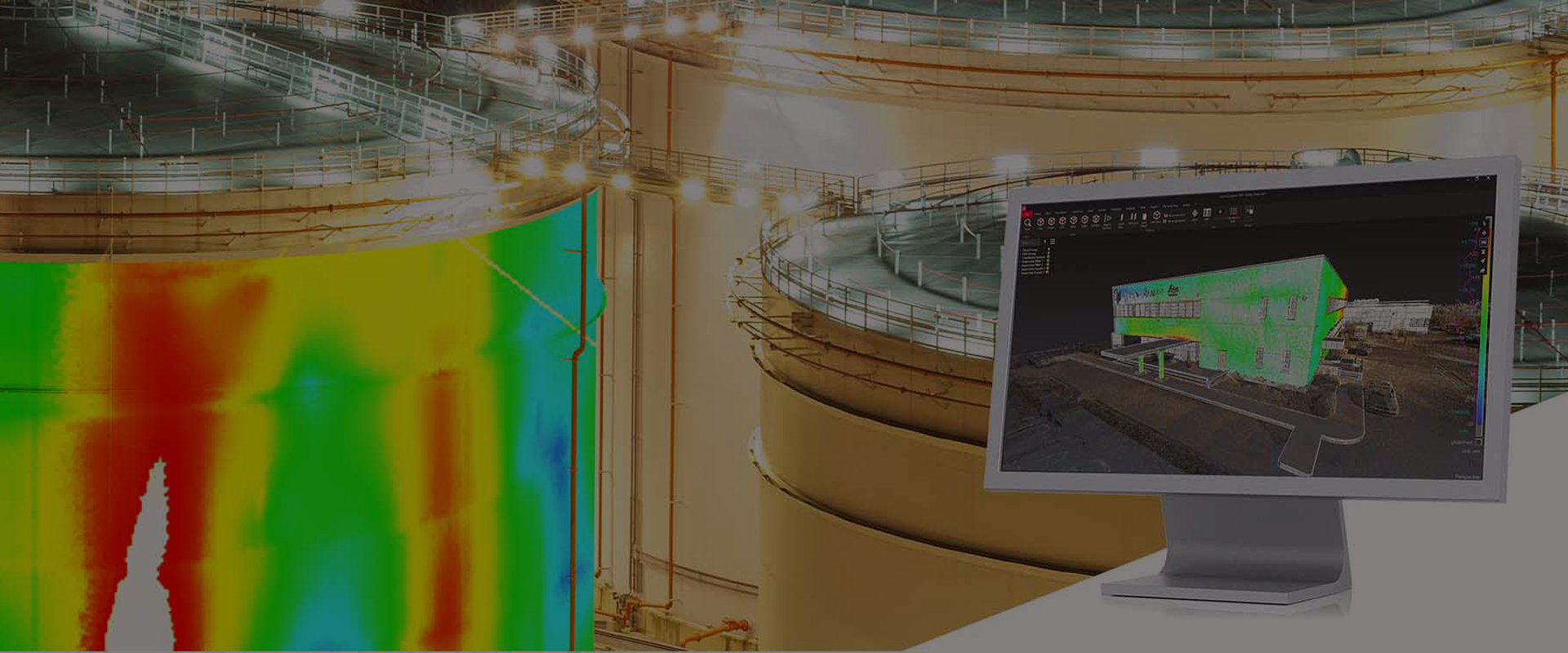

For decades, the industry relied on manual gauging using a graduated diptape or dipstick to determine tank status. More recently, companies have replaced these often hazardous and inaccurate manual methods with float and tape tank gauging, servo gauging or hydrostatic tank gauging (HTG). However, a new method – 3D laser scanning – is taking tank gauging high-tech and enabling a giant leap forward in safety, speed and accuracy.

Read the article in the Summer Edition 2018 of Tank News International.