After all, time is money. Lost production can cost $100,000 an hour in the steel industry, for example.

As plant managers strive to minimize downtime, every laser scanning job is a race against time. After all, time is money. Lost production can cost $100,000 an hour in the steel industry, for example. Despite requirements for fast turnaround, plant engineers also expect high accuracy and want to be able to interpret point clouds with ease.

Andrew Kincaid, project manager at DLZ, an architectural, engineering and field services firm with offices across the Midwest, faces these seemingly contradictory demands daily. The company has been laser scanning oil, gas and steel plants as well as bridges, roadways and buildings for over a decade. By early 2015, DLZ had three laser scanners in their arsenal. However, as clients continued to push for more high-quality information in less time, DLZ knew they needed to upgrade their scanner lineup. “After reviewing laser scanners from the major suppliers, we chose the Leica ScanStation P30. It offers fast scan speeds, high quality color images, increased operating temperature ranges and unparalleled accuracy,” explains Kincaid.

DLZ first learned about the ScanStation P30 at the SPAR International Conference, held in early April 2015, where Leica Geosystems unveiled it. The laser scanner integrates the qualities of the Leica ScanStation P20, which it replaces. These characteristics include the ability to amass one million data points per second from a range of 120 meters, capture photographs that designers can overlay on point clouds, seamless integration with workflows, and guaranteed accuracy levels made possible by real-time tilt compensation. The new scanner can also, of course, do more. “Every time Leica Geosystems comes up with a new piece of equipment, it’s a step up and forward,” says Krag Caverly, a project engineer at DLZ.

The Leica ScanStation P30 produces sharp, crisp scans and takes high dynamic range (HDR) color images, enabling the scanner to capture and reproduce subtle variations within scenes that go from bright sunlight to extreme shade. Given the speed of the P30 and the data quality, the DLZ team knew the scanner would enable them to increase productivity in the field while providing clients with highly accurate and more realistic colorized point clouds. The decision to purchase one was a logical step. The Leica ScanStation P30 has been on the job for several weeks now and is showing its prowess in a variety of jobs.

Details Make a Difference at an Oil Refinery

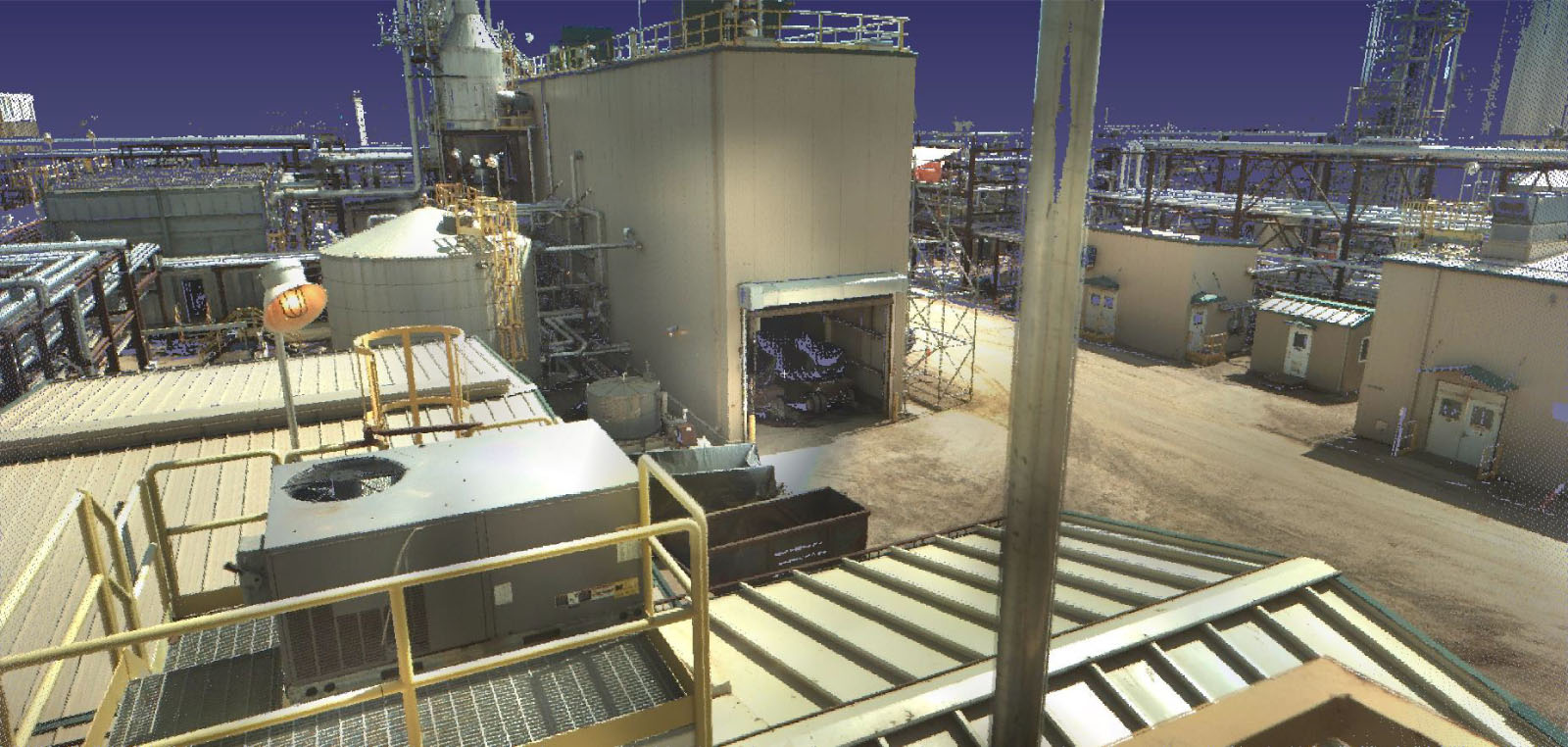

The Leica ScanStation P30 produced a crisp, high-resolution color point cloud in which it was easy to see the existing conditions and determine the best route for the new piping.

DLZ put the Leica ScanStation P30 to work at an oil refinery where engineers were integrating a new production line into the existing facility. The engineers had to thread the new pipes through the dense maze of existing piping. The Leica ScanStation P30 produced a crisp, high-resolution color point cloud in which it was easy to see the existing conditions and determine the best route for the new piping.

DLZ used Cyclone 9.0 to process the point cloud data. “Leica Geosystems has made some really nice improvements in the cloud-to-cloud registration ability as well as the capacity to filter noisy data. That’s important when working around existing production in facilities,” says Kincaid.

Cloud-to-cloud registration allows users to complete laser scanning projects with or without having targets around the scanned area. It recognizes scan overlaps and aligns them, creating groups of scans and applying an algorithmic registration. DLZ did use targets in the refinery, and Caverly was thrilled with how easily he could pick them out on the point clouds. “The resolution is so high compared to our other scanners, even at long distances. We’re able to pick out targets accurately from 120 feet away. The cloud registration is phenomenal. It’s tying together point clouds with accuracies of a 16th of an inch (1/16”). One cloud blends directly into another,” he says.

While it’s an advantage to combine point clouds, Cyclone 9.0 also makes it possible to look at small sections. Kincaid explains that this enables engineers to focus on an area of concern without having too much data at hand.

The Leica ScanStation P30 captures clean, crisp scans and takes high dynamic range (HDR) color images, making it ideal for environments with highly reflective surfaces. Sample image courtesy of Leica Geosystems.

Speed and Long-Range Scanning are Essential for Steel Mill Retrofits

Engineers were able to get in and out of areas within five to ten minutes, scan a two hundred foot tall furnace from a safe distance, and minimize interference with other workers.

A steel mill’s blast furnace has to receive a continuous supply of raw materials to be productive. A blast furnace skip incline, which moves the raw material to the top of the furnace, was misaligned and needed analysis of the existing conditions to plan the repair. Steel mill managers asked DLZ to dig into this problem and at the same time document other areas of the furnace to prepare for an upcoming extended maintenance downturn. DLZ employed the ScanStation P30 to gather data quickly and at long range.

Engineers were able to get in and out of areas within five to ten minutes, scan a two hundred foot tall furnace from a safe distance, and minimize interference with other workers. Even at this speed and distance they were able to collect high-quality data and images. “Some of the scans were in a dark area and still produced good quality images,” says Kincaid.

While they were there, they scanned most of the rest of the blast furnace in preparation for other as-built information needs that inevitably develop. Because DLZ provided the data to the plant promptly, their client was able to get back up and running quickly, producing iron.

Engineers Use Point Clouds to Fabricate Coke Battery Chutes with Confidence

A coke battery uses conveyor belts to transport raw materials in and around it and uses chutes to transfer the material to other conveyors. Over time, the chutes had deteriorated and needed to be replaced to keep the material moving without unnecessary downtime. DLZ used the ScanStation P30 to scan the chutes and capture color images. They are currently creating a 3D model of the chutes that will be used in the fabrication of the replacement chutes. This model will enable the shop to produce the perfectly-sized replacement parts off site. Once the coke battery receives them, they will be able to replace the chutes rapidly, minimizing the shutdown time. “Because of the high-resolution, colorized point cloud, nothing is left to our interpretation. Also, the speed at which we were able to gather the information was critical to our client, so the downtime needed to measure the chutes was minimized,” says Kincaid.

Crisp, high-resolution color point clouds make it easy to see existing conditions and determine the best route for the new piping. Sample image courtesy of Leica Geosystems.

Clients Demand Laser Scanning

The biggest thing is being able to gather hard-to-reach data from the ground. We don’t need scaffolding to get information.

“Without exception, our oil, gas and steel plant customers are asking for point clouds,” says Caverly. That’s because they want accurate, high-quality information with images that make it easy to interpret. For them, looking at colorized point clouds that the ScanStation P30 and Cyclone 9.0 produce is almost like looking at a picture in AutoCAD. It’s far easier than interpreting the former intensity mapped point clouds.

“I don’t know how we would do a lot of projects without laser scanning,” says Kincaid. “Our project worksites at times are hazardous and safety is always on our minds, using the best method to collect the required data safely. The biggest thing is being able to gather hard-to-reach data from the ground. We don’t need scaffolding to get information. Also, looking at a point cloud and being able to model your new piping or retrofits with confidence is invaluable. You no longer have to rely on limited information or make an additional site visit.” Given its ability to increase safety, productivity, and accuracy in engineering design, it’s not surprising that Kincaid believes clients’ demand for 3D laser scanning will continue to grow.

HIGH-VALUE DELIVERABLES

- High resolution registered point clouds

- 3D models

BENEFITS

Increased Safety

All data captured from ground level

Fast Data Collection

Speed of data capture minimized the downtime needed for measurement tasks

Comprehensive Data Capture

Complete and accurate as-is dataset can be reused for future projects

Better Project Visualization

Crisp, high-resolution color point clouds make it easy to see the existing conditions and determine the best route for new piping; even scans in dark areas produced good quality images