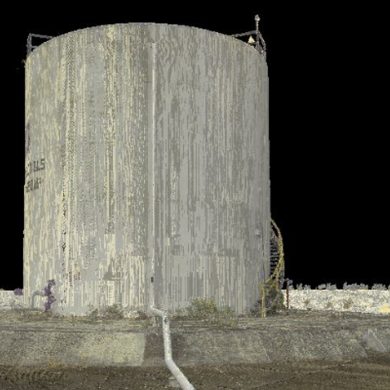

If you’re still using traditional tank gauging, you may be putting your organization at risk. Read why 3D digital tank analysis is the best approach. Read More

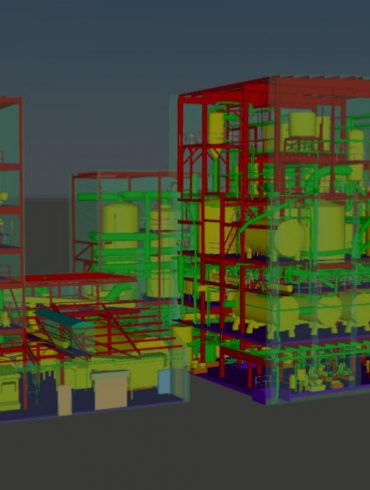

Thanks to technology advances, solutions now exist to make the transformation to automation and digitization fast, easy and cost-effective. Read More

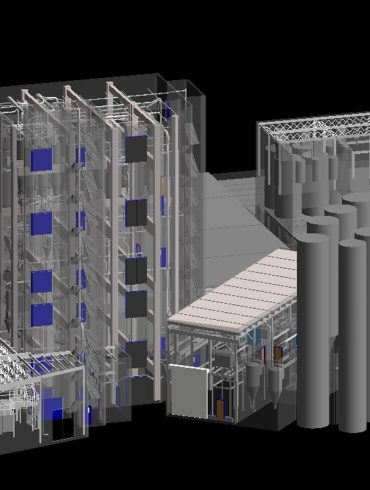

When new food storage silos need to be installed in a confined space, laser scanning offers a way to maximize safety, efficiency and mobility. Read More

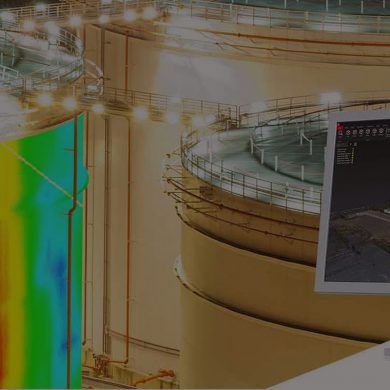

The digitalization of tank maintenance and analysis through reality capture is a proven way to increase safety and reduce risk. Read More

With the capacity to slice 22,000 tons of beets a day and produce over one billion pounds of sugar annually, the Michigan Sugar Co. is the third largest sugar… Read More

Laser scanning offers an easy and affordable way to meet documentation requirements in food and beverage processing without slowing down production. Read More

The ability to adapt and innovate its manufacturing approach positions a food processing company for continued success well into the future. Read More

A new integration of Leica Geosystems’ RTC360 technology onto Boston Dynamics agile mobile robot Spot opens new possibilities for digital remote management. Read More

Discover how to minimize or eliminate common risks through a digital remote management strategy built on a foundation of accurate, comprehensive point cloud data. Read More

An article from the Manufacturing Leadership Council details how a digital twin empowers manufacturers to be fast, agile and resilient. Read More

Explore how 3D laser scanning is taking tank gauging high-tech and enabling a giant leap forward in safety, speed and accuracy. Read More

If you haven’t yet been able to make the changes in your industrial plant that you know are needed, try starting with the data. Read More