Laser scanning offers an easy and affordable way to meet documentation requirements in food and beverage processing without slowing down production. Read More

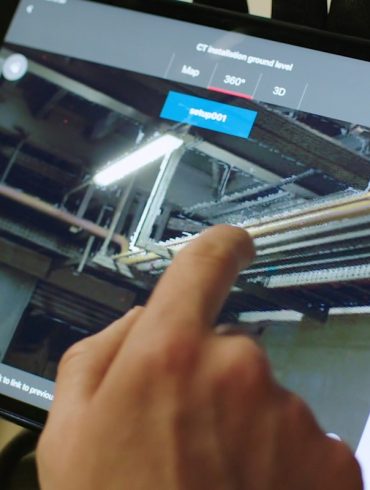

VIS technology makes it fast and easy for you to capture the as-built data you need to construct a digital twin of your plant. Read More

Watch the video to see how 3D laser scanning makes accurate digital plant documentation fast, simple and safe. Read More

Explore how 3D laser scanning is taking tank gauging high-tech and enabling a giant leap forward in safety, speed and accuracy. Read More

If you haven’t yet been able to make the changes in your industrial plant that you know are needed, try starting with the data. Read More

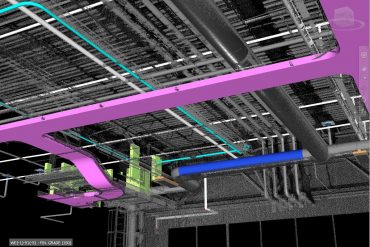

3D laser scanning is the most effective way to safely, quickly capture comprehensive and accurate measurements. Read More

An article from the Manufacturing Leadership Council details how a digital twin empowers manufacturers to be fast, agile and resilient. Read More

Starting with accurate, comprehensive digital as-built documentation on your existing facility can give you the solid foundation you need to build a successful future. Read More

When new food storage silos need to be installed in a confined space, laser scanning offers a way to maximize safety, efficiency and mobility. Read More

Thanks to technology advances, solutions now exist to make the transformation to automation and digitization fast, easy and cost-effective. Read More

Learn new and existing workflows with Cloudworx, and see how these updates can benefit your business. Read More

Laser scanning your equipment and facilities can provide the data you need to support any project you can think of in your food and beverage operations. Read More